Project Description

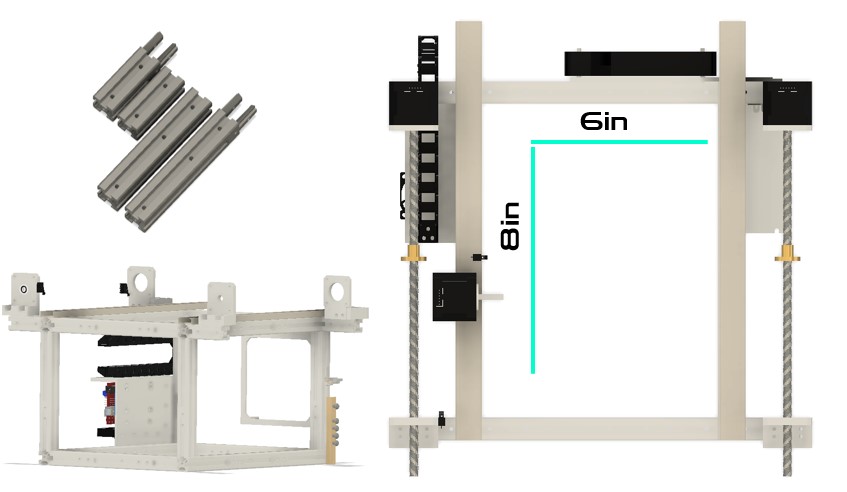

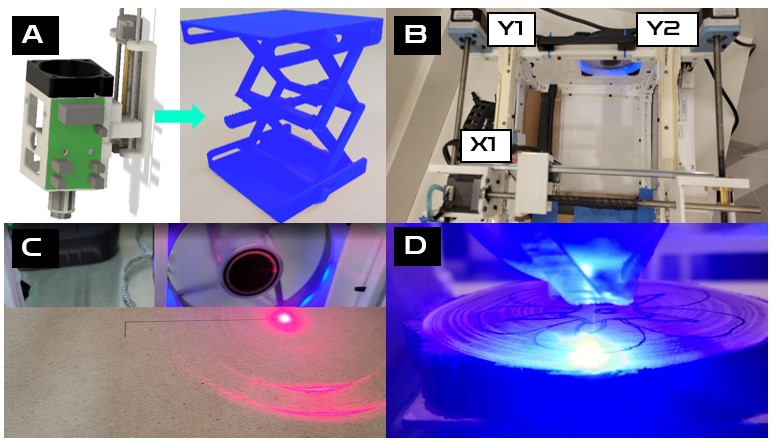

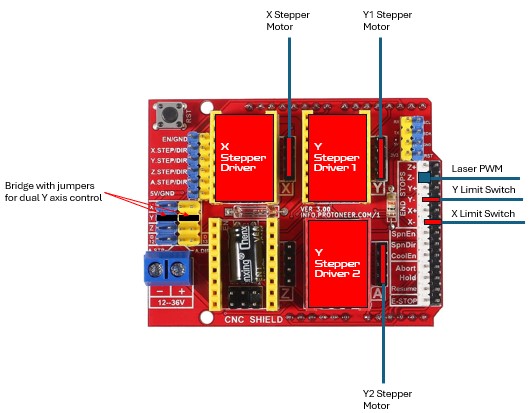

The purpose of this project was to create a 2 DOF laser cutter and engraver machine from scratch. Ideally, I wanted to make a machine that could engrave and cut wood, plastic, and other materials, and be made soley from 3D printed parts for the frame and other custom parts. I wanted to use an off the shelf laser module and stepper motors to make the machine as simple as possible. Given that the parts were all 3D printed, I wanted to make the machine as modular as possible so that it could be easily assembled and disassembled, but this came at the cost of some rigidity and vibration dampening.

In this project I will go over the design of the machine, the control system, and the results of the project, and how I over came the vibration challenges, accuracy, and other issues. I intentionally did little research when I started this project, as I wanted to see how well I could design a machine from scratch without any prior knowledge about laser cutter mechanics. I have used laser cutters in industry and school before, but they have always been large scale machines that have tons of bells and whistles auto integrated. Mostly plug and play. The laser cutter I am building should cost less than $200 to build and capable enough to cut thin wood to use in framing for future projects.

Another motivation for this project was to create a machine that could be used to make small wood burning engravings as a small side business. I've called this business Shayvin Engraving and you can find my etsy shop here. The name “Shayvin” is a blend of my name and my wife's.